Tube Laser Cutting Systems Definition

Fiber lasers have wavelengths of 1.06 microns. This wavelength is 10 percent lower than the CO2 laser beam. Fiber lasers have a much shorter wavelength which makes them more able to absorb reflective material. CO2 lasers are more likely reflect off these surfaces. Fiber laser cutting machines can be used to cut brass and copper as well as other reflective materials. The machine's laser beam, as well as the beam path, can be damaged by a CO2 laser beam reflected off the material. This risk is eliminated if the beam path is used with a fiber optic cable.

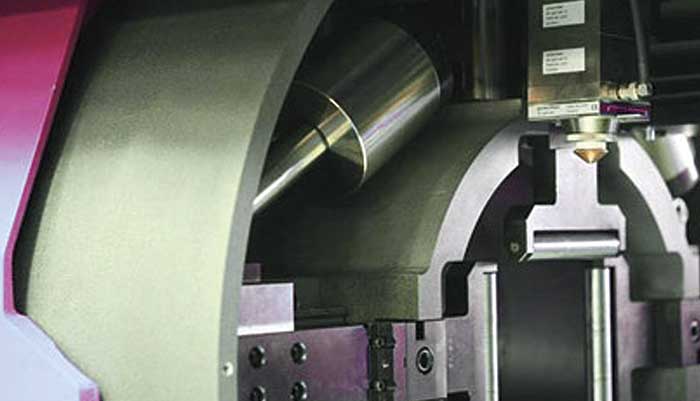

StarCut Tube L 600 may be purchased with either a fiber, USP or both lasers. StarCut Tube SL Compact Model has the smallest footprint.